- 0531-87887788

来源:/ 发布时间:2022-08-11

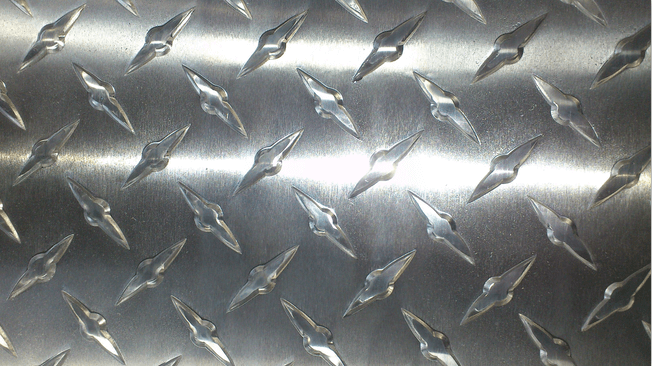

在花纹铝板生产过程中,因为设备或者人员操作失误等原因容易出现质量问题,这里小编就油污这个常见质量问题总结如下,希望铝板生产厂家能够重视该问题。

In the production process of patterned aluminum plate, quality problems are easy to occur due to equipment or personnel operation errors. Here, the small editor summarizes the common quality problems of oil pollution as follows. I hope that aluminum plate manufacturers can pay attention to this problem.

油污是质量问题中作为常见的:油污是指轧制后铝梢表面带油过多.且带上了除轧制油膜以外的多余的油,在分切生产及成品检查过程中肉眼可见的表面带油。这些油主要是由辊颈处或轧机出口上、下方甩、溅、滴在箱面上以及轧机清辊器出现异常、轧机测厚头滴油等造成,且往往较脏成分复杂。

Oil stain is a common quality problem: oil stain refers to excessive oil on the surface of aluminum tip after rolling And the excess oil other than the rolling oil film is brought, and the surface oil visible to the naked eye in the process of slitting production and finished product inspection. These oils are mainly caused by the throwing, splashing and dripping on the box surface at the roll neck or at the outlet of the rolling mill, the abnormality of the roll cleaner of the rolling mill and the dripping of oil from the thickness measuring head of the rolling mill, and they are often dirty and have complex components.

这种油污将给铝板表面带来危害较大:一是由于铝板成品多数作为装饰或包装材料,必须有一个洁净的表面;二是其厚度薄,在后续的退火时易形成泡状,而且由于油量较多在该处形成过多的残留物而影响使用。油污缺陷多少是评价铝箔质量的一项很重要指标。

This kind of oil stain will bring great harm to the surface of aluminum plate: first, because most of the finished aluminum plate is used as decoration or packaging materials, it must have a clean surface; Second, its thickness is thin, and it is easy to form bubbles in the subsequent annealing. Moreover, due to the large amount of oil, too much residue is formed at this place, which affects the use. The quantity of oil stain defect is a very important index to evaluate the quality of aluminum foil.

解决方法:在生产以前严格检查生产设备,如果一旦发现设备中油污过多要及时清洗并且查找原因,同时对生产产品进行板面清洗加工,如果清洗不掉的产品做报废处理,有油污的产品禁止入库及流入市场。

Solution: strictly check the production equipment before production. If it is found that there is too much oil in the equipment, clean it in time and find out the reason. At the same time, clean the plate surface of the production products. If the products cannot be cleaned, discard them. The products with oil are prohibited from entering the warehouse and entering the market.

划伤是质量问题的常客:划伤、擦伤、碰伤是氧化铝板表面呈现的断续或连续的单条沟状伤痕。一般是尖锐物与箔材表面接触后相对滑动时产生的。

Scratches are frequent customers of quality problems: scratches, scratches and bumps are intermittent or continuous single groove scars on the surface of aluminum oxide plate. It is generally generated when the sharp object contacts the surface of the foil and slides relatively.

产生的主要原因:轧辊、导辊表面有尖状缺陷,或粘有硬杂物;剪切、合卷、分切的机械导辊、导路有尖状缺陷或枯有杂物。

Main causes: sharp defects on the surface of roller and guide roller, or hard sundries; There are pointed defects or sundries on the mechanical guide rollers and guide paths of shearing, coiling and slitting.

6擦伤:由于物体间棱与面,或面与面接触后发生相对滑动或错动而在箱材表面造成的成束(或组)分布的伤痕。

6 scratch: the scars distributed in bundles (or groups) on the surface of the box material due to the relative sliding or staggering between the edges and surfaces of the objects or after the surface to surface contact.

简述花纹铝板常见质量问题--油污,就到这里了,如果您对此有什么了解的就赶紧来我们网站咨询更多。

Brief introduction to the common quality problems of patterned aluminum plate - oil stain, that's it. If you have any information about this, please come to our website Consult more.