- 0531-87887788

来源:/ 发布时间:2021-08-06

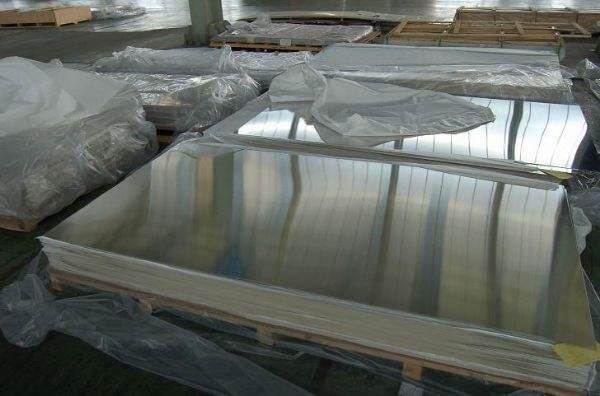

随着铝板冶炼生产技术的成熟,这一性价比高的金属材料便迅速进入人们生产生活的方方面面,成为传统金属的替代品;而在某些传统行业,铝板的市场前景尤为广泛。铝板表面划伤是铝板加工过程中比较容易发生的事,往往是因为加工处理不当,导致表面受创,严重影响到了铝板的美观性,不过划痕已经出现了,下面介绍一下铝板表面出现瑕疵的处理方法。

With the maturity of aluminum plate smelting production technology, this cost-effective metal material has quickly entered all aspects of people's production and life and become a substitute for traditional metals; In some traditional industries, the market prospect of aluminum plate is particularly broad. Scratch on the surface of aluminum plate is a relatively easy thing to happen in the process of aluminum plate processing. It is often due to improper processing, resulting in surface damage, which seriously affects the beauty of aluminum plate. However, scratch has appeared. The following describes the treatment methods for defects on the surface of aluminum plate.

铝板外表划伤能处理,简略的说有物理和化学两种办法:物理办法便是机械打磨,详细有喷砂,拉丝等,一般对于较深的划痕选用这种办法。化学办法一般选用化学试剂来抛光,简略的讲便是选用化学试剂将铝材外表腐蚀掉一层,划痕处由于有锐边,腐蚀速度快,较轻的划痕在化学抛光后能完全消除,化学抛光的材料外表光亮,好看。一般两种方法配合起来用,铝材外表能到达很好的装饰效果。

The scratch on the surface of aluminum plate can be treated. In brief, there are two physical and chemical methods: physical method is mechanical grinding, including sand blasting, wire drawing, etc. generally, this method is used for deeper scratches. Generally, chemical reagent is used for polishing. In brief, chemical reagent is used to corrode one layer of aluminum surface. Due to sharp edges at the scratch, the corrosion speed is fast. Lighter scratches can be completely eliminated after chemical polishing. The appearance of chemically polished materials is bright and good-looking. Generally, when the two methods are used together, the aluminum surface can achieve a good decorative effect.

1、铝板模具上的工作带需要打磨光滑,挤压模具的空刀是否足够,表面是否光滑。

1. The working belt on the aluminum plate die needs to be polished smooth, whether the empty knife of the extrusion die is enough and whether the surface is smooth.

2、在铝板锯切过程中:每次锯切需要及时清理锯切的切削锯末,防止二次划伤;同理在CNC加工铝板的过程中,也需要防止夹治具上面残留的铝渣划伤。

2. In the process of aluminum plate sawing: each sawing needs to clean the cutting sawdust in time to prevent secondary scratch; Similarly, in the process of CNC processing aluminum plate, it is also necessary to prevent the residual aluminum slag scratch on the clamping fixture.

3、在生产合金铝板的过程中,注意模具线条的产生,一旦产生线条,需要及时下模具,停止生产。

3. In the process of producing alloy aluminum plate, pay attention to the generation of mold lines. Once lines are generated, the mold needs to be removed in time to stop production.

4、出料轨道或摆床上有裸露的工业铝型材或石墨条内有较硬的夹杂物,应避免硬杂物与铝板接触时对铝板表面造成划伤。

4. There are exposed industrial aluminum profiles or graphite strips on the discharge track or swing bed, and there are hard inclusions in them. It is necessary to avoid scratching the surface of the aluminum plate when hard sundries contact the aluminum plate.

5、在生产和搬运的过程中要轻拿轻放,尽量避免随意拖动或翻动铝板,合理摆放铝板,尽量避免相互摩擦。

5. In the process of production and handling, handle with care, try to avoid dragging or turning the aluminum plate at will, place the aluminum plate reasonably, and try to avoid mutual friction.

除了以上五点,铝板的贮存也很关键,严禁与化学材料和潮湿性材料一同存放,很容易发生化学反应,这样做可以有效避免,其贮存环境应干燥、明亮,通风良好,无腐蚀气候,主要还是防止铝板受潮发生氧化反应,影响正常使用。

In addition to the above five points, the storage of aluminum plate is also very important. It is strictly prohibited to store with chemical materials and moist materials, which is prone to chemical reaction. This can be effectively avoided. The storage environment should be dry, bright, well ventilated and free of corrosive climate. The main thing is to prevent the oxidation reaction of aluminum plate from moisture and affect its normal use.